CNC

CNC Machining in the Input of Elements

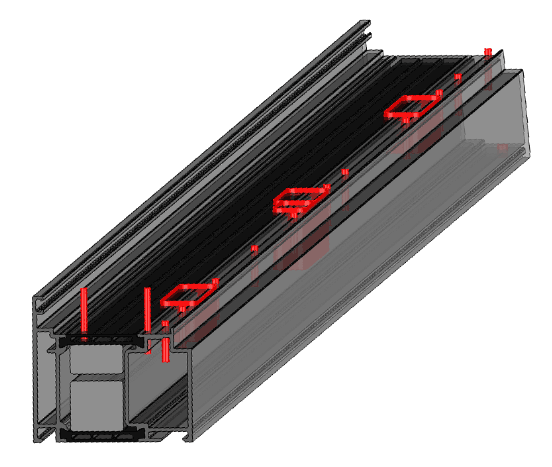

With the CNC Machining in the Input of Elements, you can create complete profile drawings with one click.

While entering your position, the program automatically determines the profile machinings for connections, notches, hardware, etc. Both the installation situation and the profiles used are checked. For example, the space that must be cleared at most for a lock case is determined. The program then determines the material to be milled and automatically creates all necessary depth tables for the machinings. The bar drawings determined in this way can be displayed as CAD drawings, on reports and in a 3D viewer.

Set up Machines

CNC Programming in three steps

Create Machinings

The basis for the machine programming are the machinings. They are created in the first step. In this chapter you will learn how to create your own machinings (e.g. drillings, circle pockets, slots, rectangular pockets, countersinks, notches, threads, etc.) and how to locate them using reference profiles.

Create Groups

Whether machinings for door hardware, profile connections and corner connectors: In the second step, the individual machinings are combined into groups. Within this group, you define on which profiles the machinings are considered in which combination. In the input of elements, the machinings will be inserted automatically.

Programming Examples

In this chapter you will find examples of how you can program machinings yourself. The instructions will guide you step-by-step through the entire process. Just click on the topic you are interested in to get more detailed information.

Tips & Tricks

Additional Material

Contact

Our technical support employees are experienced in the metal construction branch and will be pleased to answer any questions you may have about our software.

You can contact our technical support from Monday to Friday from 8:30 – 12:00am and from 1:30 – 5:00pm.

English (UK)

English (UK)